Recently a customer contacted us as he was buying a tow bar for his VW T3 from our store and he enquired about wiring in the towbar electrics.

As you know we used to run a VW T3 Specialist workshop and we have a lot of information saved, if we did a job for the first time we made notes and wrote them up to save time the second time we did the job.

One of our internal help sheets was simply the wiring colours for the rear lights and we passed this on to the customer to help with his towbar installation, I thought it would be helpful for other customers so we’ve added it to our blog to save us forwarding the same information over and over again!

As our workshop was in the UK then the following wiring colours are relevent to European models but as the UK drives on the left hand side of the road we only have a legal requirement for a rear fog lamp on the right side of the vehicle. There is no reason why we cannot have fog lamps on both sides but I presume just a cost saving exersize on the manufacturers part, this was common practice back in the day though I’m not entirly sure actually how much money a small brass tab, a bulb and a couple of metres of wire would save!

For our friends over in the USA, sorry, this isn’t for you Vanagon owners, the USA tail lights were wired differently and used what we consider the fog lamp as brake lights!

With VW being a German vehicle manufacturer then the wiring colours and terminations are to DIN 72552.

| Position | Wiring colour | Din no | Wire dia | Towbar Pin | Towbar Colour |

| Earth | Brown | 31 | 1mm² | 3 | White |

| Brake lights | Black/red | 54 | 1mm² | 6 | Red |

| Fog light | Grey/white | 55 | 1mm² | 2 | Blue |

| Left hand side light | Grey/black | 58 | 1mm² | 7 | Black |

| Right hand side light | Grey/red | 58 | 1mm² | 5 | Brown |

| Number plate lamps | Grey/green | 58 | 1mm² | ||

| Left indicator | Black/white | L | 1mm² | 1 | Yellow |

| Right indicator | Black/green | R | 1mm² | 4 | Green |

| Reverse light | Black/blue | RF | 1mm² | ||

| Left Rear Light | Pin | ||||

| Black/Red | 1 | ||||

| Grey/Black | 2 | ||||

| Brown | 3 | ||||

| *Grey/White | 4 | ||||

| Black/Blue | 5 | ||||

| Black/White | 6 | ||||

| Right Rear Light | Pin | ||||

| Black/Green | 1 | ||||

| Black/Blue | 2 | ||||

| Brown | 3 | ||||

| Grey/White | 4 | ||||

| Grey/Red | 5 | ||||

| Black/Red | 6 | ||||

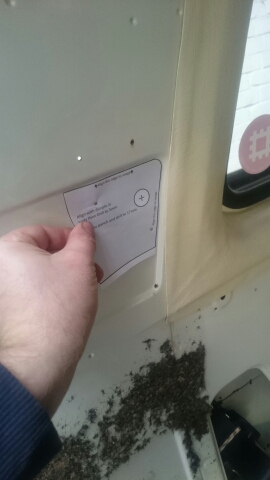

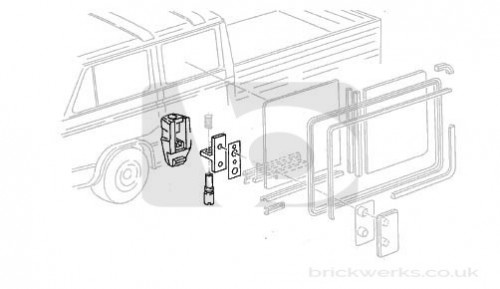

VW T3 Towbar

Universal Towbar socket