We’ve not done this for a couple of years but we’ve decided to tidy up and open the workshop doors on a weekend again and let you all have a nosey about to see what we’re up to.

Same format as previous years, we’ll be there about 9am and stick the kettle on, you bring a mug and we’ll fill it with tea or coffee.

Over the next few days we’ll sort a discount code so you can pre-order some quality stock so there’s no disappointments on the day and we’re not running around like idiots wasting time making invoices out!

We’ll sort some food out of some sort or other too.

We usually wind up around lunch time and the syncro fraternity meander their way up the valley to make a day of it and do some of the local green lanes.

For the 2WD crowd we could always cruise up the valley in a different direction to the Oil Can Cafe and check out some classic cars.

there have been some changes down at Bridge Works and we now have a lot more room in the car park so there should be plenty of space.

See you there!

Tag: t4

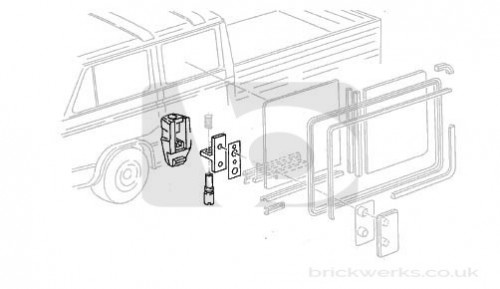

Sliding Door Window catches…

If the mails and calls we receive regularly are anything to go by, these are the bane of some T3 owners lives… and T4 and LT owners too!

So, we now stock all the available components, and in fairness the ones that fail… the Handle, the Locking Pin, Support Bracket and Internal Seal.

We’re working on the other bits, but these will make many people a bit more secure for the time being.

Westfalia Window Catch – T3, T4, LT

We’ve got the latch that attaches to the opening window, so obviously we’d need these too!

Original Westfalia items so the quality and fit is perfect.

T3 Ignition checks – Ignition coils

On a VW T3, from the factory there were 4 different ignitions coils fitted throughout the production run, one of them was only used in some African countries on models fitted with points style ignition and are unlikely to see them here so they will be glossed over.

Early vans were air cooled, the 1.6l “CT” engine and the 2.0l “CU” engine, they used what we call the early coil, it had DIN connection for the king lead, when the WBX joined the ranks then they too used the early coil. In July 1984 they swapped from the early DIN coil to the later “sawtooth” style connection at Chassis number WV2 ZZZ 25 Z EH 155 001

The later coils as fitted to everything else, these could either have a green coloured label on them or a grey label. ETKA [VW’s Electronic Parts Catalogue] is a little confusing regarding what vehicles have the green and which have the grey label, in fact the information is contradictory.

It turns out that vehicles with a grey label on their ignition coil were for vehicles with extended service intervals, basically they could go longer between having a service and as such had different 3 earth electrode spark plugs.

We feel the best way to get the right coil is just to fit what was on there originally.

A faulty ignition coil could cause a few different problems, we find that they start to give flat spots while driving, this is usually a sign they are past their best. They can be checked with a multimeter set to ohms (more on that later).

An ignition coil is basically a step up transformer encased in steel (or laterly aluminium) and filled with oil, there are 2 circuits, a primary and a secondary, the primary is the low voltage side, the secondary is where the high voltage is induced. 12v is supplied to the primary circuit and around 35000v is induced in the secondary coil which is then fed via the king lead to the distributor cap where it is dished up to the correct cylinder.

The primary circuit, this is the low voltage side, the outer terminals on the body. One is marked “15”, this is ignition live [Black wire]. The other terminal is marked “1”, this is what’s called the tachometric signal, this is the switched earth supplied by your ignition module to turn the coil on and off [Green wire].

The secondary circuit is between terminals 1 and 4, the green wire terminal and the HT output to the distributor cap.

Obviously you disconnect the electrical connections from the coil before you get busy with your Ohmmeter as you want to measure the resistance of the coil and not the rest of the ignition system too!

The expected resistances are listed in the table below.

| VW No | Bosch No | Fitted to | Primary | Secondary | |||

| Early | 211 905 115 B | 0 221 122 023 | CT, CU, DF, DG | .52Ω to .76Ω | 2.4kΩ to 3.5kΩ | Up to | 24 E 155 000 |

| Late – Green label | 211 905 115 D | 0 221 122 349 | DF,DG,DH,GW,DJ,MV,SS,SR | .5Ω to .8Ω | 2.4kΩ to 3.5kΩ | From | 24 E 155 001 |

| Late – Grey label | 191 905 115 A/B/C | 0 221 122 399 | DF,DG,SP,DJ | .6Ω to .8Ω | 6.9kΩ to 8.5kΩ |

After testing, if you find the Ohms readings are out of specification then it’s time to change the coil, it’s as simple as that!

Checking VW T4 upper ball joints

[youtube=http://www.youtube.com/watch?v=xv71gaiLSC0&feature=youtu.be]

You cannot check the ball joints on a T4 in the normal way by simply jacking the vehicle up and shaking the wheel.

The wheel has to be removed from the hub and a bar inserted between the hub carrier and the upper arm and prised apart to check for play.

We see vans quite often here that come in for service whose ball joints are as in the video above, absolutely knackered! when we show the customer they often say well, it’s just gone through an MOT!”

Changing a T4 upper ball joint takes about 1 hour per side but it does require the use of a special press to remove and replace.