One of the most common enquiries we get is with regard to changing the fuel tank.

T3’s are at that age now where if they are still on the original tank theyre very likely going to need replacing soon. So heres a little bit of information regarding tanks, and the parts that commonly need replacing when we change them.

Firstly, you’re taking the tank out, so whilst you’re doing it take the opportunity to check out whats above it, Clutch pipes, Brake Pipes, Power steering pipes, and the floor of the vehicle itself. If theyre all good, get something on there to protect them so they’ll stay that way!

Tanks… there are 3 different tanks. Early, Late, and Fuel Injection.

We’ll start with the Fuel Injection tanks as they’re the simplest.

If you have a fuel injection engine you need a fuel injection tank. This applies to standard engines and engine conversions. The difference is a larger outlet to the pump.

Early tanks were fitted up to 1985, they have a large opening for the filler neck (68mm) and the original filler neck was metal. Petrol, Diesel… all the same (except Fuel Injection!).

If you have a metal filler neck you have an EARLY Tank. Simple.

Well… not quite… see note below.

Late tanks were fitted 1985 on. Ignoring Fuel Injection engines, they are all the same again for Petrol and Diesel. They had the plastic filler neck and smaller 48mm filler hole.

So, post 1985, plastic filler neck, small hole, carb or Diesel engine… LATE tank

Like most things, its never quite that simple!

At some point after 1985 when VW realised that the metal filler neck wasn’t a great idea (anyone who has had old Golfs or Sciroccos will know all about this!) they stopped supplying a steel filler neck as a replacement part, and instead supplied a later plastic neck with a larger seal to convert the early tank.

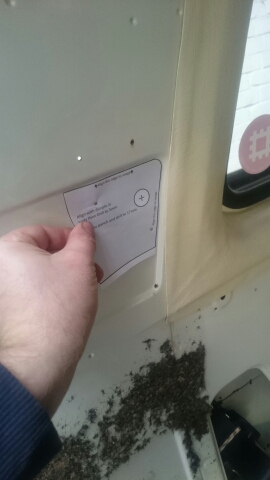

What this means is that if you have a metal filler neck you certainly have an early tank, but just because you have a plastic one it doesn’t necessarily follow that you have a late one! The simplest way to tell for sure is to look through the hole in the chassis, you’ll be able to see the rubber seal. If need be, send us a photo and we should be able to ID it.

If you do have an early tank with a plastic filler neck (utilising the larger seal), you’re better off swapping to the late tank and normal seal… why? Simply because the seal is about £5 cheaper 🙂

Okay, that’s the tank out of the way. So what else do you need?

Its a tricky one. We replace a lot of tanks, and a lot of the time the original components can be re-used. A lot of the time some need replacing. Sometimes they all need replacing. Some things might not need replacing, but it kind of makes sense as its all in bits anyway. So, we can’t really tell you exactly what you’ll need… just give you a breakdown of all the parts available.

Well start at the filler neck and work down.

Filler Surround:

https://www.brickwerks.co.uk/index.php/t3-fuel-filler-surround.html

and Seal:

https://www.brickwerks.co.uk/index.php/fuel-filler-neck-rubber-t3.html

Retaining ring for seal (we fit a stainless one, but we also have a cheaper steel one):

https://www.brickwerks.co.uk/index.php/fuel-filler-neck-metal-ring-stainless.html https://www.brickwerks.co.uk/index.php/fuel-filler-neck-metal-ring-steel-with-screws.html

And the hose clip for the neck seal.

https://www.brickwerks.co.uk/index.php/fuel-filler-neck-metal-ring-steel-with-screws.html

Then, to the bottom of the filler neck (The plastic filler neck itself rarely fails and isn’t available):

Early Seal:

https://www.brickwerks.co.uk/index.php/fuel-tank-filler-grommet-t3-early-68mm.html

Late Seal:

https://www.brickwerks.co.uk/index.php/fuel-tank-filler-grommet-late-48mm.html

And the seal to allow a plastic filler neck to be used on an early tank:

https://www.brickwerks.co.uk/index.php/fuel-tank-filler-grommet-t3-convert-early-late.html

Onto the tank itself…

There are 3 grommets in the top of the tank for the breather system. At the time of updating this only aftermarket are available:

https://brickwerks.co.uk/product/breather-grommet-t3-fuel-tank-all-2wd-alternative/

And the breather balance pipe:

https://brickwerks.co.uk/product/fuel-tank-breather-balance-pipe-t3-2wd/

Braided hose from the breather pipe to the arch tanks (1metre will replace them all):

https://www.brickwerks.co.uk/index.php/5-5mm-textile-overbraid-hose.html

or if you want to fit the really good stuff:

https://brickwerks.co.uk/product/fuel-hose-ethanol-bio-safe-5-5mm-2/

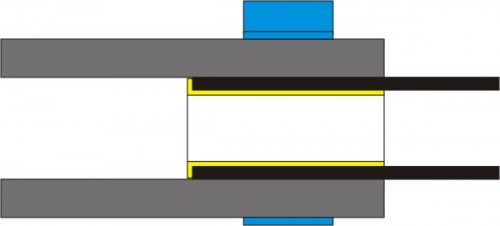

Then the sender… 2 options, early and late:

https://www.brickwerks.co.uk/index.php/fuel-level-sender-t3-2wd-upto-1986.html

https://brickwerks.co.uk/product/fuel-level-sender-t3-86/

And the sender seal. Tanks come with a new seal. Throw it away, they’re hard and almost impossible to fit properly. Likewise the seals that come with the level senders.

Often the best seal is the one you remove from the old tank! If you do want to fit a new seal, its this one:

https://www.brickwerks.co.uk/index.php/fuel-level-sender-seal-t3-2wd.html

And that should do you… we’d also recommend something to coat the tank and protect the area above the tank. We use Dintrol, one can should be enough to do the tank and above.

https://www.brickwerks.co.uk/index.php/dinitrol-4941-underbody-sealant-0-5l.html

https://www.brickwerks.co.uk/index.php/dinitrol-4941-underbody-sealant-1-0l.html

As always, our “Early/Late” calculator may help with identifying what you have from your chassis number.

There you go, I dont think we’ve missed anything… theres more you could replace but thats the stuff on the tank itself.