When installing an alternative engine into the place of a T3 Diesel engine then it’s sometimes neccesary to upgrade the clutch to handle the increased torque from the engine.

It’s quite common practice on VW T3 Diesels to install AAZ engines (1.9l TD with indirect injection), GTI engines (usually 2E or AGG) or indeed TDI (1.9 Direct Injection engines such as 1Z, AFN etc) engines as they are from the same AE827 engine series and are pretty much VW Lego.

The original 215mm clutch and flywheel from the VW T3 D / TD will bolt in and work with these engines but for a GTI and AAZ engines then the original 215mm clutch will be marginal if it will slip or not, a properly installed TDI engine will most definatley slip.

There are a couple of things we can offer to help you get your extra power through to the gearbox without slipping on your engine conversion.

The single mass flywheel and clutch is only really recommended for the AAZ and GTI engines, the Dual mass flywheel is recommended for the TDI.

The 228mm single mass will work with the TDI but the dual mass affords a little more protection for the gearbox and the associated harmonic vibrations that the TDI produces that can manifest in horrible rattles from the nose end of the gearbox. It is well known that gearboxes with TDI conversions will suffer accelerated wear due to extra low end torque and harmonics.

The fitting of either of these clutch systems to a T3 is not straight forward job and other parts and modifications are required.

- The clutch input shaft needs to be swapped to an item with 28 splines as opposed to the original 24 splined shaft.

- The original flywheel cover plate will foul the larger flywheel and needs to be swapped for an alternative flat set up.

- The clutch release bearing that is supplied with the SMF or DMF are not correct for the T3, an original T3 item is to be used.

- The flywheel is bigger and as such will foul the inside of the bellhousing, the bellhousing will need to be ground down in a couple of places to give flywheel clearance to turn.

- The nose of the original T3 Diesel starter motor will now foul the flywheel ring gear and the starter nose will either need to be ground slightly or replaced with a TDI starter and starter adapter

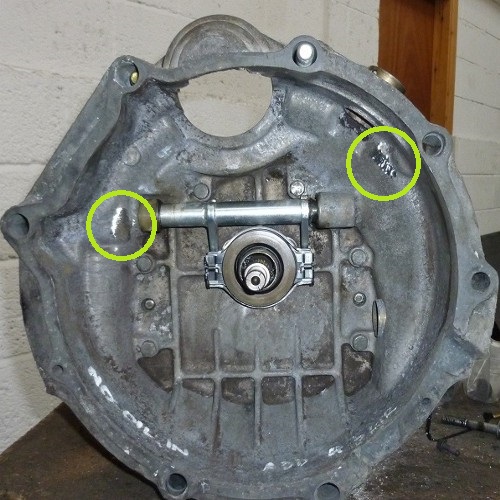

Please see the following 3 pictures that will show you where to grind the inside of the bellhousing, for this you will need a die grinder with a rotary burr that’s suitable for Aluminium and a small angle grinder such as something that accepts Roloc discs.

Failure to grind these places will result in the engine becoming locked when the bellhousing to engine bolts are fully tightened.

Once the bellhousing is modified then the whole set up can be assembled as normal.

Please be aware that the timing marks will now be missing and you’ll have to mark your own, we suggest that you use the “Full Stop Method” (Sometimes called Positive Stop or Dead Stop method) for accuracy, this is well documented on the internet and beyond the scope of this quick guide.